5.4 转子加工中的数控工艺

5.4.1 概述

目前,数控编程方法主要有手工编程和自动编程两种。

1.手工编程

通过取相应的坐标点,按加工制订的轨迹由手工写程序代码。

2.自动编程

① 基于PRO/E为平台:建立转子三维模型→按加工流程构建加工序列→生成APT语言的.ncl文件,如图5.55所示。

② 基于ICAM平台利用转子车床后置处理器对.ncl文件进行后置处理,获得符合机床格式的加工程序(G代码),如图5.56所示。

③ 基于VERICUT平台利用转子车削仿真系统对加工程序(G代码)进行模拟加工仿真,并进行优化,获得最合理的加工程序,如图5.57所示。

图5.55 基于PRO/E平台的自动编程

图5.56 基于ICAM平台的自动编程

图5.56 基于VERICUT平台的自动编程

5.4.2 转子加工中的典型数控工艺及NC代码

1.菌型轮槽数控车削加工

· 粗车进汽侧凸台

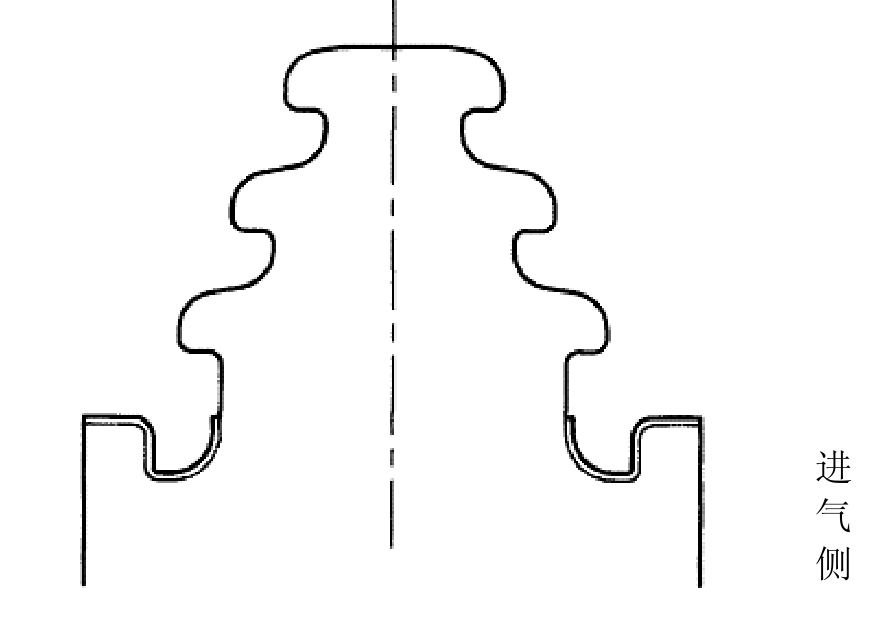

菌型轮槽进汽侧凸台的加工图,如图5.57所示。

图5.57 菌型轮槽进汽侧凸台的加工图

其NC代码为:

;SPF8151

;X889.1mm(YE LUN ZHONG XIN)

;RH SIDE

N10 M06

N20 T31 D1 ;TYP 3 RECHTS AUSSEN

N30 SPF999

N40 G97 G00 X1700.

N50 Z28.55

N60 X929.1

N70 G01 G96 X909.1 F5

N80 X789.346 F1.5

N90 Z33.55 F5

N100 G00 G97 X929.1

N110 Z21.825

N120 G01 G96 X909.1 F5

N130 X818.518 F1.5

N140 Z26.825 F5

N150 G00 G97 X929.1

N160 Z15.095

N170 G01 G96 X909.1 F5

N180 X849.509 F1.5

N190 Z20.095 F5

N200 G00 G97 X1700

N210 M17

· 凸台倒圆

菌型轮槽凸台倒圆的加工图,如图5.58所示。

图5.58 菌型轮槽凸台倒圆的加工图

其NC代码为:

;SPF8153

;X889.1mm(YE LUN ZHONG XIN)

;RH SIDE

N10 M06

N20 T136 D1 ;TYP 3 RECHTS AUSSEN

N30 SPF999

N40 G97 G00 X1700.

N50 Z1.479

N60 X909.7

N70 G01 G96 X899.7 F5

N80 G03 X889.7 Z6.479 K5 F0.5

N90 G02 X889.546 Z7.356 I-5.05

N100 G01 X888.536 Z10.222

N110 G02 X878.589 Z14.395 I-4.973 K-0.877

N120 G01 X858.444

N130 X857.543 Z16.952

N140 G02 X847.596 Z21.125 I-4.973 K-0.877

N150 G01 X827.455

N160 X826.555 Z23.677

N170 G02 X816.608 Z27.85 I-4.973 K-0.877 N180 G01 X792.64

N190 X802.64 Z32.85 F3

N200 Z45

N210 X792.64

N220 Z27.85 F0.5

N230 X802.64 Z32.85 F3

N240 G00 G97 X1700

N250 M17

· 粗车横槽

横槽的加工图,如图5.59所示。

图5.59 横槽加工图

其NC代码为:

;SPF8155

;X889.1mm(YE LUN ZHONG XIN)

;RH SIDE HENG CAO CU CHE

;up nut

N10 M06

N20 T40 D1 ;TYP 2 RECHTS AUSSEN

N30 SPF999

N40 G97 G00 X1700.

N50 Z17.395

N60 X909.1

N70 G01 G96 X872.236 F5

N80 Z10.3 F0.15

N90 Z17.395 F5

N100 G41 X884.589

N110 G03 X878.589 Z14.395 I-3 F0.15

N120 G01 X876.166

N130 G02 X872.236 Z12.43 K-1.965

N140 G01 G40 Z24.125 F5

N150 T41 D1 ;TYP 3

N154 STOPRE

N156 G01 G42 X841.596

N160 G02 X847.596 Z21.125 I3 F0.15

N170 G03 X857.543 Z16.952 K-5.05

N180 G01 X859.028 Z12.742

N190 G02 X861.638 Z10.3 I4.382 K0.773

N200 G01 G40 Z24.125 F5

;midle nut

N210 T40 D1 ;TYP 2

N220 STOPRE

N230 G01 X841.248 F5

N240 Z17.03 F0.15

N250 Z24.125 F5

N260 G41 X853.596

N270 G03 X847.596 Z21.125 I-3 F0.15

N280 G01 X845.178

N290 G02 X841.248 Z19.16 K-1.965

N300 G01 G40 Z30.85 F5

N310 T41 D1 ;TYP 3

N320 STOPRE

N330 G01 G42 X810.608

N340 G02 X816.608 Z27.85 I3 F0.15

N350 G03 X826.555 Z23.677 K-5.05

N360 G01 X828.038 Z19.472

N370 G02 X830.649 Z17.03 I4.382 K0.773

N380 G01 G40 Z30.85 F5

;bottom nut

N390 T40 D1 ;TYP 2

N400 STOPRE

N410 G01 X807.79 F5

N420 Z22.52 F0.15

N430 G04 S1

N440 G01 Z30.85 F5

N450 G41 X810.26

N460 Z23.755 F0.15

N470 G03 X807.79 Z22.52 I-1.235

N480 G01 G40 Z30.85 F5

N490 G41 X822.608

N500 G03 X816.608 Z27.85 I-3 F0.15

N510 G01 X814.19

N520 G02 X810.26 Z25.885 K-1.965

N530 G01 G40 Z43 F5

N540 T41 D1 ;TYP 3

N550 STOPRE

N560 G01 X792.64

N570 Z22.52 F0.15

N580 G04 S1

N590 G01 Z43 F5

N600 G00 G97 X1700

N610 M17

· 粗车外包

外包的加工图,如图5.60所示。

图5.60 外包加工图

其NC代码为:

;SPF815_5

;X889.1mm(YE LUN ZHONG XIN)

;LH SIDE wai bao cu che

N10 M06

N20 T54 D1 ;TYP 4 RECHTS AUSSEN

N30 stopre

N40 G97 G00 X1700.

N50 Z-44.7

N60 X901.1

N70 G01 G96 X802.04 F10

N80 Z-29.327 F3

N90 X778.467 Z-22.522 F0.1

N100 G01 X802.04 Z-29.327 F3

N110 Z-44.7

N120 G00 G97 X1700

N130 M06

N140 T79 D1 ;TYP 9

N150 STOPRE

N160 G00 X1700

N170 Z-49.7

N180 X901.1

N190 G01 G96 X812.64 F10

N200 G41 X792.64 F3

N210 Z-33.415 F0.15

N220 G02 X788.71 Z-31.45 I-1.965

N230 G01 X781.38

N240 G03 X778.38 Z-29.95 K1.5

N250 G01 G40 X791.38 F3

N260 X801.69 Z-32.95

N280 Z-49.7

N270 G00 G97 X1700

N280 M17

· 半精车轮槽工作面

车轮槽工作面的加工图,如图5.61所示。

图5.61 车轮槽工作面加工图

·半精车槽角度面及齿深

槽角度面及齿深加工图,如图5.62所示。

图5.62 槽角度面及齿深加工图

其NC代码为:

;SPF8157

;X889.1mm(YE LUN ZHONG XIN)

;RH SIDE semi-finshing

;up nut

N10 M06

N20 T63 D1 ;TYP 9 RECHTS AUSSEN

N30 stopre

N40 G97 G00 X1700.

N50 Z19.095

N60 X909.1

N70 G01 G96 X869.436 F5

N80 Z10.415 F0.15

N90 Z19.095 F5

N100 X893.1

N110 G41 Z14.245

N120 G01 X876.066 F0.15

N130 G02 X872.436 Z12.43 K-1.815

N140 G01 Z10.415

N150 G03 X869.436 Z8.915 I-1.5

N160 G01 X867.792

N170 G40 Z25.825 F5

N180 X838.448

N190 G01 Z17.145 F0.15

N200 Z25.825 F5

N210 X862.107

N220 G41 Z20.975

N230 X845.078 F0.15

N240 G02 X841.448 Z19.16 K-1.815

N250 G01 Z17.145

N260 G03 X838.448 Z15.645 I-1.5

N270 G01 X836.802

N280 G40 Z32.55 F5

N290 X807.46

N300 G01 Z23.87 F0.15

N310 Z32.55 F5

N320 X831.119

N330 G41 Z27.7

N340 X814.09 F0.15

N350 G02 X810.46 Z25.885 K-1.815

N360 G01 Z23.87

N370 G03 X807.46 Z22.37 I-1.5

N380 G01 X799.34

N390 G40 Z27.7 F5

N400 T64 D1 ;TYP 9

N410 STOPRE

N420 G42 X807.46

N430 X816.608 F0.15

N440 G03 X826.26 Z23.651 K-4.9

N450 G01 X827.742 Z19.446

N460 G02 X836.802 Z15.645 I4.53 K0.799

N470 G01 G40 Z23.975 F5

N480 G42 X845.078 Z20.975 F0.15

N490 G01 X847.596

N500 G03 X857.248 Z16.926 K-4.9

N510 G01 X858.732 Z12.716

N520 G02 X867.792 Z8.915 I4.53 K0.799

N530 G01 G40 Z17.245 F5

N540 G42 X876.066 Z14.245 F0.15

N550 X878.589

N560 G03 X888.24 Z10.196 K-4.9

N570 G01 X889.251 Z7.33

N580 G03 X889.4 Z6.479 I-4.826 K-0.851

N590 G02 X899.4 Z1.479 I5

N600 G01 G40 X919.1 F5

N610 G00 G97 X1700

N620 M17

· 半精车进外包槽

进外包槽的加工图,如图5.63所示。

图5.63 进外包槽的加工图

其NC代码为:

;SPF815_6

;X889.1mm(YE LUN ZHONG XIN)

;RH SIDE wai bao ban jing che

N130 M06

N140 T82 D1 ;TYP 9

N150 STOPRE

N160 G00 X1700

N170 Z49.7

N180 X901.1

N190 G01 G96 X812.64 F10

N200 G42 X792.34 F3

N210 Z33.415 F0.15

N220 G03 X788.71 Z31.6 I-1.815

N230 G01 X781.08

N240 G02 X778.08 Z30.1 K-1.5

N250 G01 G40 X791.38 F3

N260 T81 D1 ;TYP 9

N270 STOPRE

N280 G01 G41 X782.164 Z23.943 F0.15

N290 G03 X778.08 Z28.52 I4.108 K4.577

N300 G01 G40 X788.08 F1

N301 x793.38 z29.315

N310 X812.34 Z33.415 F3

N320 G00 G97 X1700

N330 M06

N340 T52 D1 ;TYP 9

N350 STOPRE

N360 G00 X1700

N370 Z49.7

N380 X901.1

N390 G01 G96 X812.34 F10

N400 Z33.415

N410 G41 X803.29 Z27.152 F3

N420 X796.38 Z22.37 F0.15

N430 X790.38

N440 G03 X780.164 Z25.095 K6.15

N450 G01 G40 X812.34 Z33.415 F3

N460 G00 G97 X1700

N470 M17

· 精车轮槽工作面

轮槽工作面的加工图,如图5.64所示。

图5.64 轮槽工作面的加工图

· 精车槽角度面及齿深

槽角度面及齿深的加工图,如图5.65所示。

图5.65 槽角度面及齿深的加工图

其NC代码为:

;SPF8159

;X889.1mm(YE LUN ZHONG XIN)

;RH SIDE finshing

;up nut

N10 M06

N20 T63 D1 ;TYP 9 RECHTS AUSSEN

N30 stopre

N40 G97 G00 X1700.

N50 Z19.095

N60 X909.1

N70 G01 G96 X869.736 F5

N80 Z10.3 F0.15

N90 Z19.095 F5

N100 X893.1

N110 G41 Z14.095

N120 G01 X876.066 F0.15

N130 G02 X872.736 Z12.43 K-1.665

N140 G01 Z10.3

N150 G03 X869.666 Z8.765 I-1.535

N160 G01 X867.792

N170 G40 Z25.825 F5

N180 X838.748

N190 G01 Z17.03 F0.15

N200 Z25.825 F5

N210 X862.107

N220 G41 Z20.825

N230 X845.078 F0.15

N240 G02 X841.748 Z19.16 K-1.665

N250 G01 Z17.03

N260 G03 X838.678 Z15.495 I-1.535

N270 G01 X836.802

N280 G40 Z32.55 F5

N290 X807.76

N300 G01 Z23.755 F0.15

N310 Z32.55 F5

N320 X831.119

N330 G41 Z27.55

N340 X814.09 F0.15

N350 G02 X810.76 Z25.885 K-1.665

N360 G01 Z23.755

N370 G03 X807.69 Z22.22 I-1.535

N380 G01 X799.34

N390 G40 Z27.55 F5

N400 T64 D1 ;TYP 9

N410 STOPRE

N420 G42 X807.46

N430 X816.608 F0.15

N440 G03 X825.964 Z23.625 K-4.75

N450 G01 X827.447 Z19.42

N460 G02 X836.802 Z15.495 I4.678 K0.825

N470 G01 G40 Z23.975 F5

N480 G42 X845.078 Z20.825 F0.15

N490 G01 X847.596

N500 G03 X856.952 Z16.9 K-4.75

N510 G01 X858.436 Z12.69

N520 G02 X867.792 Z8.765 I4.678 K0.825

N530 G01 G40 Z17.245 F5

N540 G42 X876.066 Z14.095 F0.15

N550 X878.589

N560 G03 X887.945 Z10.17 K-4.75

N570 G01 X888.956 Z7.304

N580 G03 X889.1 Z6.479 I-4.678 K-0.825

N590 G02 X899.1 Z1.479 I5

N600 G01 G40 X919.1 F5

N610 G00 G97 X1700

n620 m06

n630 t65 d1 ;ty9

n640 stopre

n650 g00 z32.55

n660 x901.1

n670 g01 g96 g41 x899.1 f5

n680 g01 x805.34 f30

n690 g01 x804.34 z22.22 f1

n700 g01 x791.34 f0.5

n710 z25.22 f1

n720 g01 g40 x807.46 z32.55 f5

n730 g01 x899.1 f30

n740 g00 g97 x1700

N750 M17

·轮槽工作面修正

轮槽工作面的加工图,如图5.66所示。

其NC代码为:

;SPF815_2

;X889.1mm(YE LUN ZHONG XIN)

;RH SIDE jie ju xiu zheng

图5.66 轮槽工作面的加工图

;up nut

N10 M06

N20 T63 D1 ;TYP 9 RECHTS AUSSEN

N30 stopre

N40 G97 G00 X1700.

N50 Z14.095

N60 X909.1

N70 G01 G96 G41 X893.1 F5

N80 G01 X876.166 F0.15

N90 G02 X872.836 Z12.43 K-1.665

N100 G01 Z10.3

N110 G03 X869.766 Z8.765 I-1.535

N120 G01 X867.792

N130 G40 Z20.825 F5

N140 G41 X862.107

N150 X845.178 F0.15

N160 G02 X841.848 Z19.16 K-1.665

N170 G01 Z17.03

N180 G03 X838.778 Z15.495 I-1.535

N190 G01 X836.802

N200 G40 Z27.55 F5

N210 G41 X831.119

N220 X814.19 F0.15

N230 G02 X810.86 Z25.885 K-1.665

N240 G01 Z23.755

N250 G03 X807.79 Z22.22 I-1.535

N260 G01 X799.34

N270 G40 Z32.55 F5

N280 G00 G97 X1700

N290 M17

·精车外包槽

外包槽的加工图,如图5.67所示。

图5.67 外包槽的加工图

其NC代码为:

;SPF815_8

;X889.1mm(YE LUN ZHONG XIN)

;RH SIDE wai bao jing che

N130 M06

N140 T82 D1 ;TYP 9

N150 STOPRE

N160 G00 X1700

N170 Z49.7

N180 X901.1

N190 G01 G96 X812.64 F10

N200 G42 X792.04 F3

N210 Z33.415 F0.15

N220 G03 X788.71 Z31.75 I-1.665

N230 G01 X780.85

N240 G02 X777.78 Z30.215 K-1.535

N250 G01 G40 X791.38 F3

N260 T81 D1 ;TYP 9

N270 STOPRE

N280 G01 G41 X781.946 Z23.839 F0.15

N290 G03 X777.78 Z28.52 I4.217 K4.681

N300 G01 G40 X788.08 F1

n301 x793.38 z29.315

N310 X812.34 Z33.415 F3

N320 G00 G97 X1700

N330 M06

N340 T52 D1 ;TYP 9

N350 STOPRE

N360 G00 X1700

N370 Z49.7

N380 X901.1

N390 G01 G96 X812.34 F10

N400 Z33.415

N410 G41 X803.29 Z27.152 F3

N420 X796.38 Z22.22 F0.15

N430 X790.38

N440 G03 X779.896 Z25.025 K6.3

N450 G01 G40 X812.34 Z33.415 F3

N460 G00 G97 X1700

N470 M17

· 检验

加工完成后,按图5.68进行检验。

图5.68 菌型轮槽检验图

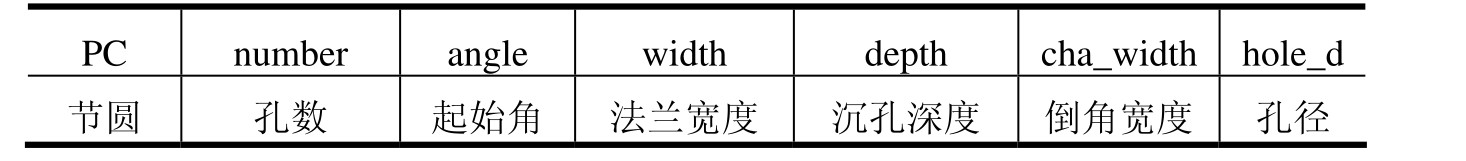

2.靠背轮连接结孔镗削加工

靠背轮连接孔镗削加工图,如图5.69所示。其加工流程:预钻底孔→粗镗→反镗沉孔→精镗→孔口倒角。

图5.69 靠背轮连接孔镗削加工图

根据转子法兰连接孔的对称结构特征,从简化程序的设计角度考虑,我们将其加工程序按工艺流程设计成通用程序如下:

%_N_MPF001_MPF

;coupleing_hole_maching

def real pc,number,angle,width,depth

def real cha_width,hole_d

pc=

number=

angle=

width=

depth=

cha_width=

hole_d=

N0240 MSG("Drilling")

N0250 G54 M06 T01 D1

N0260 G00 Z50 W0

N0270 G00 X0 Y0

N0280 M03 S200 F100

N0290 MCALL CYCLE81(50,0,10,,width+30)

N0300 HOLES2(0,0,pc/2,angle,,number)

N0310 MCALL

N0320 G00 Z50

N0330 M05

M00

N0340 MSG("ROUGH BORING")

N0250 G54 M06 T01 D1

N0260 G00 Z50 W0

N0270 G00 X0 Y0

N0280 M03 S800 F100

N0290 MCALL CYCLE81(50,0,10,,width+10)

N0300 HOLES2(0,0,pc/2,angle,,number)

N0310 MCALL

N0320 G00 Z50

N0330 M05

M00

N0440 MSG("COUNTER hole BORING")

N0450 G54 M06 T02 D1

N0460 G00 Z100 W0

N0470 G00 X0 Y0

N0480 MCALL ChenKong

N0490 HOLES2(0,0,PC/2,angle,,number)

N0500 MCALL

N0510 G00 Z100

N0520 M05

M00

N0530 MSG(“FINISHING BORING”)

IF HOLE_D=“70”

N0540 G54 M06 T03 D1

N0550 G00 Z50 W0

N0560 G00 X0 Y0

N0570 M03 S1000 F20

N0590 MACLL CYCLE86(50,0,10,,depth+5,3,3,−1,0,0,0)

N0600 HOLES2(0,0,pc/2,angle,,number)

N0610 MCALL

N0620 M05

N0630 G00 Z50

N0640 M00

ELSE

GOTO LABEL1

ENDIF

MSG("CHAMFER cha_widthX45")

N10 G54 M06 T05 D1

N20 G00 Z50 W0

N30 S800 M03

N40 G00 X0 Y0

N50 MCALL DaoJiao

N60 HOLES2(0,0,pc/2,angle,,number)

N70 MCALL

N80 M05

N90 Z50

N100 LABEL1:M30

参数说明

子程序:

%_N_chenkong_spf

def real width,depth

width=

depth=

N0010 G00 Z100

N0020 SPOS=0

N0040 G91 X−2

N0030 G01 Z= −(width+10)F400

N0040 G91 X2

N0050 M04 S800 F100

N0060 G90 Z= −depth

N0070 SPOS=0

N0080 G91 X−2

N0090 G90 Z100 F400

N0100 M17

%_N_daojiao_spf

def real cha_width,hole_d

cha_width=

hole_d=

N10 G0 Z=cha_width

N40 G91 G01 G41 G64 X=hole_d/2−10 Y=hole_d/2−(hole_d/2−10)F=400

N50 G03 X=−(hole_d/2−10)Y=hole_d/2−10 CR=hole_d/2−10 F=150

N60 G03 X0 Y0 I0 J=-hole_d/2

N70 G03 X=−(hole_d/2−10)Y=−(hole_d/2−10)CR=hole_d/2−10

N80 G01 G40 X=hole_d/2−10 Y=−(hole_d/2−(hole_d/2−10))F=400

N80 G90 G60

N90 G00 Z=50

N100 M17

免责声明:以上内容源自网络,版权归原作者所有,如有侵犯您的原创版权请告知,我们将尽快删除相关内容。